Tensile Strength Test Identifies Filler Metal Properties

A tensile strength test is a testing method to determine the strength of a welded joint. This test is performed as part of a quality assurance process. It can also be performed in conjunction with other tests, such as hydrostatic pressure testing, to ensure that welds meet specific standards.

Understanding the durability and flexibility offered by a filler metal is crucial — and a tensile strength test can provide that information.

Filler metal manufacturers perform tensile testing on many of their products for several reasons. Like many end users, they may perform tensile testing to help monitor process quality. Manufacturers use tensile testing to determine and maintain product classifications and approvals from agencies such as the American Welding Society (AWS) or the American Bureau of Shipping (ABS).

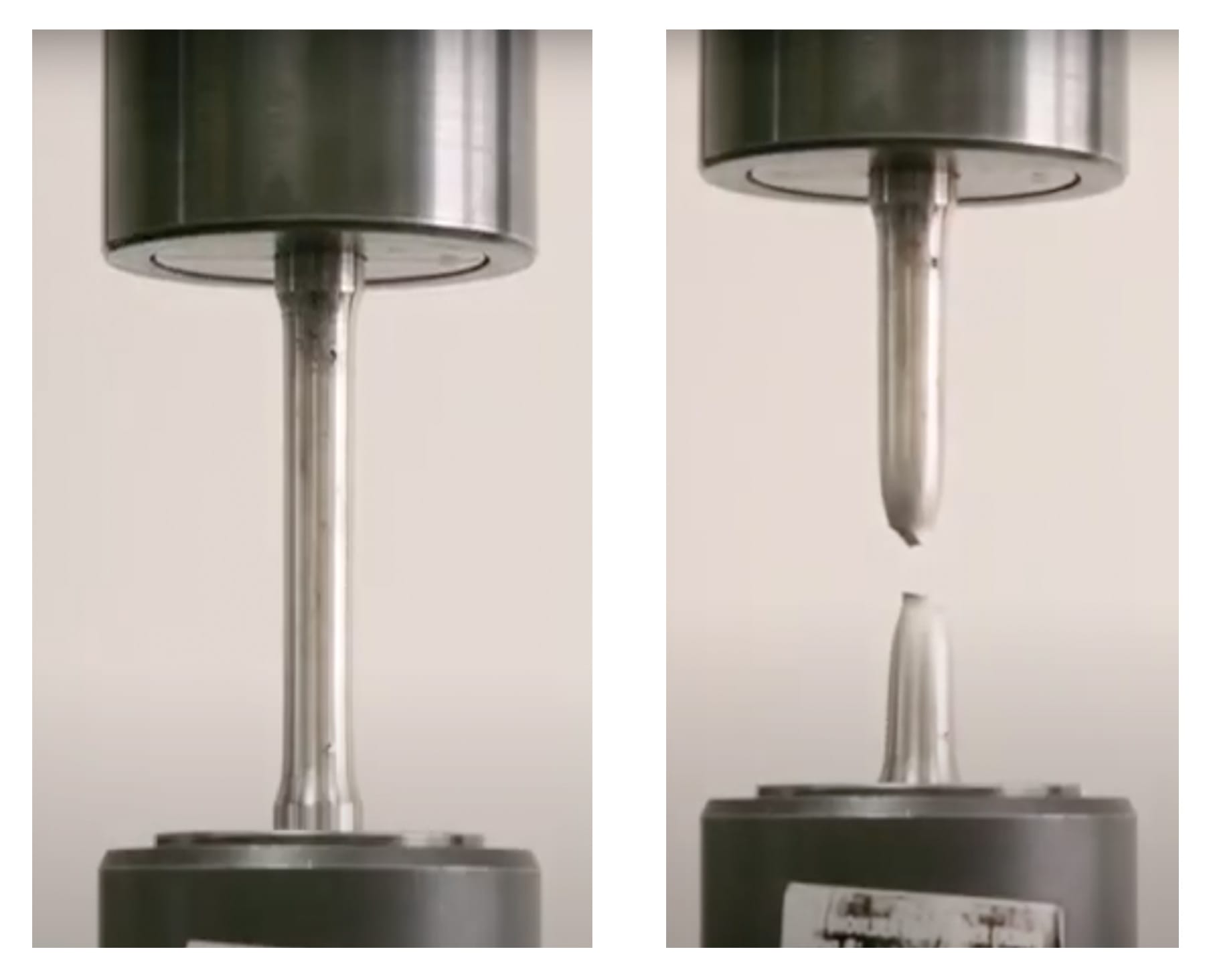

Watch as Robert Fox, marketing specialist and welding engineer at Hobart, explains the process of tensile strength testing. The test requires multiple steps. First, a test plate is created and machined to be a weld specimen. Ultimately, it will be subject to pulling force until the point of breaking. Specialized equipment measures the maximum amount of stress the specimen is able to withstand to provide valuable tensile strength values.

You can find tensile test data on product data sheets specific to your filler metal on the Hobart Brothers website.