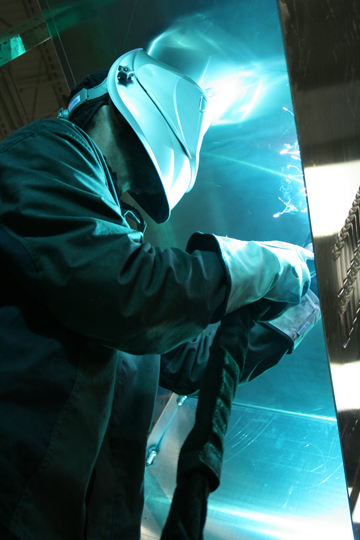

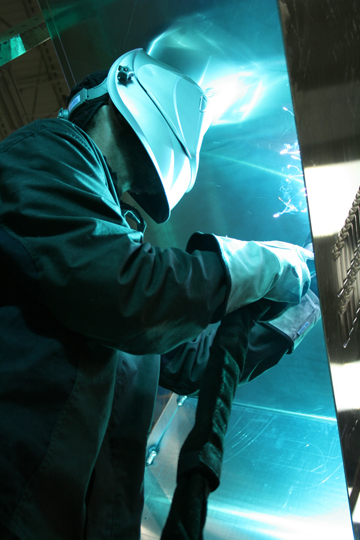

Welding Aluminum: Troubleshooting Questions Answered

Quickly and efficiently rectifying problems in the welding operation can go a long way in helping minimize downtime and unnecessary costs. Learning how to prevent the problems in the first place is even more beneficial, regardless of the material being used for the application. In particular, aluminum poses some unique challenges. In addition to a low melting point and high thermal conductivity, aluminum is especially prone to burnthrough on thinner sections and may experience lack of fusion on thicker parts. Weld defects such as cracking, weld smut/soot and porosity are also real concerns.

weight ratio, as well as its high electrical conductivity,

make it an excellent choice for everything from

aerospace applications to heat exchangers, trailer

fabrication and most recently, automotive body

panels and frames.

Still, aluminum’s corrosion resistance and high strength-to-weight ratio, as well as its high electrical conductivity, make it an excellent choice for everything from aerospace applications to heat exchangers, trailer fabrication and most recently, automotive body panels and frames.

To avoid a negative impact on productivity and quality, it is important to understand the causes of aluminum weld defects, implement steps to prevent them and find ways to quickly rectify errors should they occur. Here are answers to some common questions to help troubleshoot the process.

What are the causes of common types of cracking in aluminum welding?

Hot cracking and stress cracking are possible when using either the gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW) process on aluminum. Both types of cracks can prevent welds from meeting code requirements and can eventually lead to weld failure, even when the cracks are small. Hot cracking is predominately a matter of chemistry, while stress cracking is the result of mechanical stresses.

There are three main factors that influence the probability that hot cracking will occur during aluminum welding. One, how susceptible the aluminum base material is to cracking; some alloys, like 6000 series, are more prone to the problem. Two, the filler metal being used during the process. Three, the most appropriate joint design; some joint designs restrict the addition of filler metal.

Stress cracking can occur when an aluminum weld cools and excessive shrinkage stresses are present during solidification. This could be due to a concave bead profile, too slow of a travel speed, a highly restrained joint, or depression in the end of the weld (crater crack).

What steps can prevent cracking in aluminum welds?

To prevent hot cracking, choose a filler metal that provides a weld metal chemistry with lower crack sensitivity. Each aluminum filler metal features an American Welding Society (AWS) classification that corresponds to the Aluminum Association registration number, and together the two identify the particular alloy chemistry. Always reference a reputable filler metal selection guide to make the best choice, since not all aluminum filler metals are suitable for every aluminum base material. Some aluminum filler metal guides give particular recommendations specifically for several weld characteristics, namely: cracking, strength, ductility, corrosion resistance, elevated temperature service, color match after anodizing, PWHT, and toughness. If cracking is a concern, select the filler metal that has the highest rating in the cracking category.

Also help prevent hot cracking by using an appropriate joint design. A beveled groove joint is a good option. It allows for the addition of greater amounts of filler metal, which increases the amount of base metal dilution, making it less prone to cracking.

Sometimes stress cracking can be prevented by using a filler metal containing silicon, when allowable. This type of filler metal lowers shrinkage stresses, particularly in crack-sensitive areas like the beginning and end of the weld (or craters). Also, use an automated crater fill function or other approved methods of crater filling to minimize the opportunity for cracking in the crater. Increasing travel speeds can help reduce the opportunity for stress cracking on aluminum by narrowing the heat affected zone (HAZ) and reducing how much the base metal melts. Preheating is also an option to defend against stress cracking, since it helps minimize residual stress levels in the base material during and after welding. It is important to monitor the heat input closely; too much heat can lower base material tensile strength in some alloys to unacceptable levels.

What’s the best way to prevent burn-through or lack of penetration on aluminum?

Using a Pulsed GMAW welding process is a great defense against burnthrough on aluminum that is 1/8 inch or thinner. Power sources with this capability operate by switching between a high peak current and low background current. In the peak current phase, a droplet from the aluminum wire pinches off and propels toward the weld joint, while during the low background current phase, the arc remains stable without metal transfer. The combination of these high peak and low background currents reduces heat input to prevent burnthrough and offers the added benefit of creating little to no spatter.

is important to understand the causes of aluminum weld

defects, implement steps to prevent them and find ways

to quickly rectify errors should they occur.

When welding thicker sections of aluminum it’s particularly important to have enough amperage to adequately penetrate the weld joint. A good general rule of thumb is that it takes about 250 amps to weld 1/4-inch thick aluminum and about 350 amps to weld 1/2-inch thick aluminum. In some instances, adding helium to the shielding gas mixture may be desired for its ability to provide a hotter, more penetrating arc on thicker sections. For the GMAW process, a mixture of 75 percent helium balanced with 25 percent argon is a good option. Use a mixture of 25 percent helium and 75 percent argon when GTA welding thicker sections of aluminum to increase penetration.

What’s the best way to prevent discoloration of aluminum welds?

Discoloration and smut occur when aluminum and/or magnesium oxides collect on the base material and weld. This phenomenon is most common when MIG welding and occurs because as the filler wire passes through the arc and melts, some of it reaches the vaporization temperature and condenses on the cooler base metal that is not adequately protected by the shielding gas. Reduce the opportunity for this problem by choosing the appropriate filler metal. For example, a 4000 series aluminum filler metal contains little to no magnesium, which reduces the opportunity for this element to vaporize into the arc and condense on the weld in the form of soot (as compared to 5000 series aluminum filler metals which contain about 5% magnesium).

Shortening the contact-to-work-distance (CTWD) and using the appropriate gun angle and shielding gas flow rate can also minimize weld discoloration. Use a push angle, which helps drive the cleaning action from the arc in front of the weld to help remove smut. Increasing the nozzle size of the GMAW gun or GTAW torch helps protect the arc from drafts that could introduce oxygen into the process. Always keep the nozzle clean of spatter to ensure consistent shielding gas flow to protect the weld pool.

What is the best way to prevent porosity in aluminum weld joints?

Porosity is a common discontinuity when welding aluminum. It primarily occurs when hydrogen enters the weld pool during melting and then gets trapped in the weld during solidification. There are several ways to prevent this problem. First, be certain that the base metal and the filler metal are clean and dry. Wipe down the aluminum prior to welding, using a solvent and clean cloth to remove any paint, oil, grease or lubricants that could introduce hydrocarbons into the weld. Then brush the weld joint with a clean stainless steel brush dedicated for the job. If the aluminum base material has been stored in a cool location, allow it to acclimate to the temperature in the shop for 24 hours before beginning the welding process to prevent condensation from forming on the aluminum. Storing unpackaged filler metals in a heated cabinet or room can also help reduce the risk of porosity. It can prevent the products from cycling through dew points and minimizes hydrated oxide development on the surface of GMAW wires or GTAW cut lengths. Purchasing filler metals from a reputable manufacturer is always a good idea, as these companies typically diamond shave the wires and GTAW cut lengths to eliminate harmful oxides and follow procedures to produce low residual hydrogen containing compounds. Finally, consider purchasing low dew point shielding gases as protection against porosity. Follow all recommended welding procedures for shielding gas flow rates and purge cycles.

Last thoughts

As with any welding process and the welding of any material, following some basic guidelines is critical to obtaining the best results. With aluminum, its mechanical and chemical composition can make the process a bit tricky. Always follow best practices for cleaning and storing the material and filler metals, and carefully select the right equipment. After all, having everything in order before welding is easier than trying to fix problems later.