Seamless MEGAFIL Welding Wires

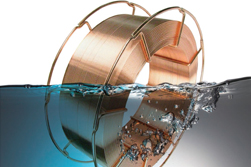

Hobart® MEGAFIL® welding wire (metal-cored and flux-cored) features an exciting seamless technology that provides extreme resistance to moisture pick up, helping reduce cracking risks and making them the ideal choice for field applications where climates can be challenging.

The addition of low diffusible hydrogen values further aids in mitigating cracking risks. A copper coating improves feedability and provides optimal current transfer.

Hobart MEGAFIL® seamless flux- and metal-cored wires are hermetically sealed and totally insensitive to moisture absorption, even under extreme climatic conditions such as tropical temperatures with very high relative humidity. The filling remains dry throughout the entire process of storage and use in welded fabrication, minimizing the risk of hydrogen-induced cracking caused by moisture in the consumable. MEGAFIL welding wires require no special storage conditions. We do not recommend re-drying items before using them.

Storage recommendations for MEGAFIL welding wire are as follows:

- Store wires under dry conditions in the original sealed packaging.

- Avoid contact between wire and substances such as water or any other kind of liquid, vapor, oil, grease or corrosion.

- Do not touch the wire surface with bare hands.

- Avoid exposure of the wire below the dew point. Do not leave unprotected wire spools in workshops overnight.

For more guidance on MEGAFIL welding wire and other filler metals to use in your industry, explore our collection of Technical Articles.