Filters:

-

Industry

-

Media

-

Hobart Family of Wires Reduces Manganese Levels

Watch as Tim Hensley, product manager, discusses the Element™ family of low manganese wires from Hobart. These products can help...

Learn More

-

Fort Defiance Relies on Hobart Filler Metals

How do you ensure your weld strength meets U.S. Department of Defense standards? For Fort Defiance Industries (FDI), Hobart 4943...

Learn More

-

FabCOR Metal-Cored Wire Helps Taylor Improve Quality

At Mississippi-based Taylor Machine Works, weld appearance is just as important as weld integrity. The company gains both with Hobart...

Learn More

-

Hobart Showcases FabCOR® Wire FABTECH 2015

Jonathan Will, product manager at Hobart, shares the benefits of welding galvanized steel with FabCOR® F6 wire, including a reduction...

Learn More

-

Hobart Helps Manufacturer Switch to Metal-Cored Wire

Hobart worked with Webster Industries to assess its welding processes and convert the company to metal-cored wire. The result? Better...

Learn More

-

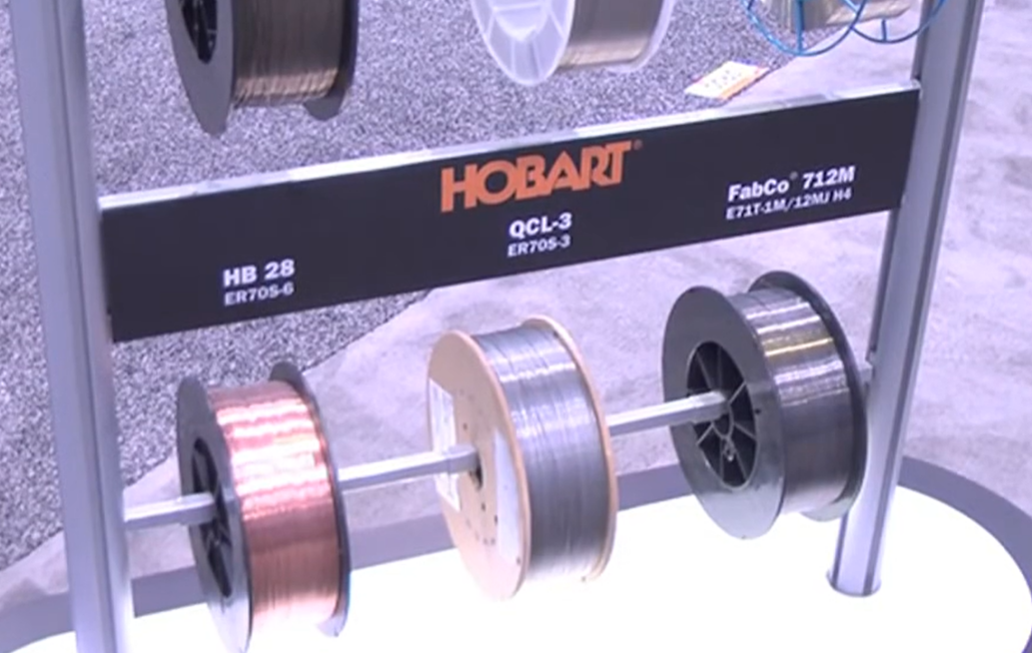

Hobart Brothers at Fabtech 2011

Bruce Morrett discusses the filler metals, including tubular wires, solid wires and stick electrodes, featured at the FABTECH 2011 show...

Learn More