Metal-Cored Wire and Robotic Welding: A Combination for Productivity

Quality. Productivity. Cost. All three factor into the decision to implement welding automation. With an eye toward improvement, many companies find that a welding robot can offer the precision and speed needed to gain a competitive edge. They take great care in making the equipment selection, arranging the robotic weld cell and training the proper personnel to oversee it. But what about the welding wire?

For many applications, including those in the automotive industry, where materials like galvanized and aluminized steel are becoming more prevalent due to their high strength-to-weight ratio, metal-cored wire has proven to be a beneficial addition to many robotic welding operations. It also excels in smaller welding operations and/or those where standard steel is used. The benefits are especially true when compared to solid wire, which many consider to be the industry standard. Conversions from solid wire to metal-cored wire can support the push toward greater productivity, in particular, by way of faster travel speeds and higher deposition rates — sometimes as much as 20 to 30 percent more.

Metal-cored wire is a tubular filler metal filled with metallic powders and alloys. Because of this wire’s structure, it carries higher current densities than solid wire of the same diameter (at equivalent amperage settings), allowing for more weld metal to be placed in a joint in less time.

found in the weld cell. This filler metal also provides advantages

throughout the pre- and post-weld areas of many welding operations.

The productivity benefits provided by metal-cored wire, however, aren’t just found in the weld cell. This filler metal also provides advantages throughout the pre- and post-weld areas of many welding operations.

In the weld cell

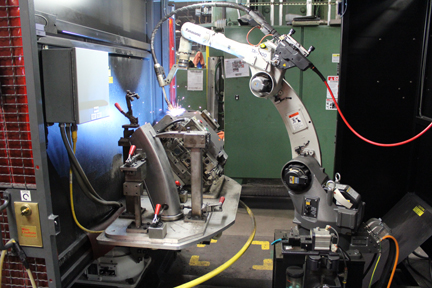

In any robotic welding cell, repeatability is key. The robot needs to produce the same weld over and over — and quickly — to provide companies with the best quality in the shortest amount of time. Whether it’s in today’s automotive applications, where the drive is toward lighter, thinner, stronger materials that can meet upcoming fuel requirements, or in a shop producing lower volume parts — accuracy is non-negotiable.

When paired with metal-cored wire, robotic welding can offer some key benefits directly in the weld cell, namely, broad arc that can bridge gaps and provide a smooth weld bead appearance; arc stability and minimal weld pool turbulence, resulting in better deposition efficiency; and consistent arc starting and wire feeding for high weld quality.

While metal-cored wire excels with a standard spray transfer process for materials above 1/16 inch, when welding thinner parts, such as automotive engine cradles or frames, pairing this filler metal with a modified short circuit process is necessary. This combination provides the best quality and travel speeds on flat and horizontal welding positions. It can also minimize subsurface porosity that is prone to occur when welding materials like galvanized steel, and it helps lower heat input to reduce the risk of burnthrough.

When welding with metal-cored wires in out-of-position applications, pulsed welding programs are necessary to control the fluidity of the weld pool. It is important to consult with a trusted filler metal manufacturer or welding distributor for options for filler metals applications, as there are also certain American Welding Society (AWS) classifications of metal-cored wire that perform better in these applications than others. Metal-cored wires paired with a pulsing program can offer benefits when welding in-position, too, particularly with robots offering seam-tracking capabilities; the pulsing action shortens the arc, making the weld puddle more manageable and lowering heat input into the part. They also work well to remove the zinc oxide coating when welding galvanized steel.

Companies should consider packaging and wire diameter when implementing metal-cored wire into a robotic welding application. Look for payout drums that feed the wire with the appropriate cast so that it feeds smoothly and makes a consistent connection with the contact tip to provide the best arc starting. Depending on the thickness of material, companies can also increase the diameter of wire being used, which puts the robot in a position to place a greater amount of weld metal in the joint in a shorter period of time.

Using a heavy-duty contact tip, such as a chrome zirconium, one can help ensure the best performance from metal-cored wire. These tips can better withstand the high volume of wire passing through for longer periods of time than standard-duty contact tips. That means less downtime for changeover, which helps support the greater productivity sought with metal-cored wire when paired with a robot.

Metal-cored wire in pre- and post-weld areas

In robotic welding operations — no matter the industry — there are typically many activities that take place in the pre- and post-weld areas. These can range from pre-cleaning of the base material and applying anti-spatter before welding to removing spatter and/or powder coating parts after. In many cases, metal-cored wire can eliminate some of these steps.

Activities like tacking parts or loading fixtures, of course, are simply non-negotiable in the pre-weld area. To obtain the best quality, it is critical for these to occur and to be addressed accurately. Because metal-cored wire has added deoxidizers, alloys and arc stabilizers, however, it generates very little to no spatter and can weld through some contaminants. This advantage can reduce the time and cost for companies to apply anti-spatter, as well as the time needed to clean it from fixtures, flooring and the robot, and eliminate the need for grinding and sandblasting.

By removing such pre-weld activities, companies operating robotic welding systems can then reduce the associated time, labor and costs in this area of the robotic welding operation and send parts straight to the weld cell.

In the post-weld-area of a robotic welding operation, metal-cored wire offers some of its best advantages — namely it can reduce cleanup and rework. Because metal-cored wire offers good gap bridging and a smooth weld bead, and reduces instances of burnthrough, weld quality is typically quite high when coming out of the robotic welding cell; there is less need for rework. The way that the wire burns off also reduces opportunities for spatter, so post-weld grinding isn’t typically required.

By eliminating these activities, companies can increase the flow of completed parts to other stages of production, such as painting or coating, to improve overall productivity. It may also be possible to lower labor costs and gain a faster return on their robotic welding system investment by reallocating labor elsewhere in the welding operation to gain even higher productivity levels.

Because the goal of any robotic welding operation is to have high arc-on time and high quality to drive productivity, it is important to look at facets of the application — the wire included. In some applications, metal-cored wire may be the element that helps a company gain that competitive edge.