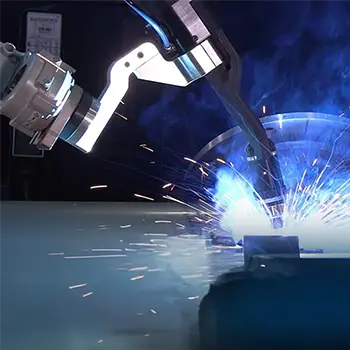

High Potential – A new automated MIG welding system offers high deposition rates and high weld quality

Originally published in Welding Productivity https://fsmdirect.com/high-potential/

Like most manufacturers in high-production environments, those in the heavy fabrication industry — the producers of heavy equipment, agricultural and earthmoving equipment, and truck and trailer fabricators — constantly aim to improve productivity and quality without making their operations more complex.

To improve the deposition rates of automated MIG welding in the heavy fab industry without overcomplicating operations or adding the cost of a new automated welding cell, a new automated MIG welding system is available. This means faster weld times, which leads to increased productivity and efficiency.

Deposition processes

There are plenty of ways for a manufacturer to ramp up their deposition rates. The problem, however, is that many of them add complexity and oftentimes additional cost to the operation — the exact opposite of what a business owner wants. Take submerged arc welding as an example.

Submerged arc welding delivers on the need for high deposition rates as well as high arc-on times, and it’s used to make single- and multi-pass welds in relatively thick plate.

“Submerged arc welding can achieve a deposition rate of 40 pounds per hour,” says Seth Perrin, advanced welding product specialist, Miller Electric Mfg. LLC. “But it is limited by the type of joint configuration and is impractical to fully automate. It is typically used for fixed, mechanized, linear welds. It is also limited in its deposition efficiency. The process produces a lot of slag, so you lose a lot of that deposited metal, and that slag has to be removed.”

Robotic tandem welding is another arc welding process that can increase deposition rates, but this type of welding is complicated in its design (using two welding wires with two independent arcs running in tandem) and programming requirements. Torch accessibility can also be an issue; when the torch is bigger in size, it can be difficult to reach tight areas.

“Tandem welding brings complexities,” Perrin says. “You’re dealing with two wires, two wire feeders and two power sources. It requires a larger equipment investment, which is complex and cumbersome to maintain and keep up and running. The skill needed to operate it is at a pretty high level.”

While another option to increase deposition rates is to go up to the next size wire diameter in a welding process, some manufacturers just put down more of the wire they are already using with the same equipment.

“But, it is hard to maintain that arc,” Perrin says. “Pretty much, you’re over-exerting the capabilities of the process. Arc stability goes out the window, more spatter is produced and weld quality starts to deteriorate. Most current systems are optimized to the point that anything increased, whether that be in volts, amps or travel speed, will create arc instability and poor weld.”

The next level

The new system that is available, however, takes a different approach to high deposition welding. The Hercules automated MIG welding system boosts productivity by delivering a gain of up to 30 percent and possibly more in deposition rates over a typical MIG welding system and corresponding productivity with no loss of weld integrity. It is for robotic welding with long welds in the flat and horizontal welding positions.

Even operations that have optimized their MIG welding processes for high deposition welding can benefit from the Hercules welding system.

“A manufacturer can look at it this way,” Perrin says. “If you are maxed out on deposition rates and travel speeds because you can’t increase wire feed speeds with your current welding process, but you don’t have the capital to go out and buy another robotic cell or invest in other processes, that’s where Hercules comes into play. You don’t have to make as big of an investment but can still get up to a 30 percent increase in productivity.”

Four inputs are involved in making the Hercules welding system work effectively. Developed by Miller, Hobart and Tregaskiss, the system combines two power sources, a wire feeder, a unique torch design and a specialized metal-cored wire.

The Hercules system works well because the Miller® Auto-Continuum™ 500 and XMT® 450 CC/CV power sources work together with the Hercules Drive to deliver what the system needs.

“In order to get high deposition rates, say 20 pounds and higher, you’re going to need higher amperages,” Perrin says. “Typically, for higher levels of deposition, you have to go up in wire size. Because you’re feeding more wire, you need more amps to maintain that arc.”

With the Auto-Continuum 500 establishing and maintaining the arc, it’s the second power source, the XMT 450 CC/CV, that provides one of the keys to the Hercules system’s success. “We’re doing something special where we have a secondary power source preheating the wire prior to it entering the welding arc,” Perrin says.

What are the benefits of preheating? Perrin explains: “To melt the solid-state wire and maintain that arc, you need X amount of energy. It takes a certain amount of energy to take something from a solid state (in this case the wire) and turn it into a molten puddle. With the addition of preheating the wire prior to it entering the arc, we can reduce the amount of energy needed to melt the wire.

“The Auto-Continuum has a duty cycle of 500 amps,” he continues. “If we were to feed 650 ipm of wire without preheating, it would require 500 to 600 amps to sustain that arc. By preheating the wire, we can achieve the same wire feed rate while the Auto-Continuum only needs approximately 350 or 400 amps to maintain the arc. This preheating process allows for improved arc stability, resulting in a visually appealing and precise arc.”

Puzzle pieces

Another part of the system is the Tregaskiss® Hercules robotic MIG gun. The design of this system is tailored to seamlessly integrate with the two power sources. It incorporates two contact tips, each with distinct functions. The first contact tip operates in a manner similar to traditional welding processes, generating the welding arc. Positioned just before it, the second contact tip is responsible for delivering the crucial preheating element. Together, these contact tips work in tandem to optimize the welding process and achieve the desired results. Also, the gun’s water-cooled design delivers superior cooling to the front-end consumables.

The final piece of the puzzle is the Hobart® FabCor® Hercules gas-shielded metal-cored wire that can accommodate faster travel speeds to deliver the system’s high deposition rates and productivity while maintaining arc stability. The wire offers robust mechanical properties for heavy equipment applications where weld integrity, performance and aesthetics are key considerations. It maintains good bead appearance and contour, even when welding at high speeds.

Summing up the Hercules system, Perrin says, “Every shop out there is optimized. Their current equipment and processes are optimized to their highest capacity. They can’t get any more out of them without deteriorating weld quality. So what can they do? Hiring more people might not be an option today, especially in more rural areas. And maybe they aren’t profitable enough to go out and purchase a new $300,000 automated cell. But they might have enough to invest in a Hercules system that can gain them up to 30 percent in deposition rates and even higher,” he adds. “It’s just giving the customer another tool and another option for automated robotic welding.”