Getting to Know Flux-Cored Wires

There is no single filler metal solution for every job. The mechanical and chemical properties of the base material, the required welding position, the available equipment and the welding operator’s skill set, among other considerations, all factor in making the best selection.

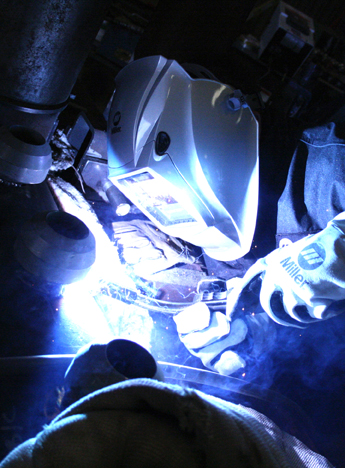

For applications where companies seek to gain productivity through higher deposition rates, flux-cored wires are often a viable option. These wires are known to excel in performance and weld quality in industries ranging from general fabrication and manufacturing to construction, offshore and shipbuilding.

Flux-cored wires have unique welding characteristics and requirements, advantages and limitations. Knowing these can help in determining whether flux-cored wires are the right choice.

This article has been published as a web-exclusive with thefabricator.com. To read the entire story by Hobart product manager, Jonathan Will, please click here.