GET MORE EFFICIENCY, MORE EASILY

Comprehensive Construction and Fabrication Solutions

Hobart® filler metals are highly adaptable for shop or field work and come with the support of our team of experts. Our products are also easy to integrate into existing workflows and have premium weldability, so they’ll deliver high-quality welds across a wide range of applications and conditions.

Be sure to check out these case studies and see how easy it can be to meet project deadlines and increase efficiency.

Why Choose Hobart® Filler Metals?

Highly Adaptable to Many Applications

Enhances Your Team’s Productivity

Robust Mechanical and Reduced Defects

Discover Our Range of Filler Metals

FabCO® Triple 7

FabCOR® Elevate™

Fabshield® XLR-8™

Explore Other Confab Solutions

METAL-CORED

FabCOR® Element™ XP

FabCOR® 86R

SUB-CORED

SubCOR™ EM13K-S MOD

FLUX-CORED

FabCO® Excel-Arc™ 71

FabCO® XLNT-6

FabCO® RXR

STICK

Hobart® 418

Hobart® 610

Hobart® 335A

A Custom Filler Metal Solution for the San Francisco-Oakland Bay Bridge

Mechanical Materials Engineer – Portland State University

Senior Research Engineer – Portland State University

Talk with a Confab Expert

Get in touch with Hobart to find the right solution for your business

"*" indicates required fields

Resources for the Confab Industry

Metal-Cored Wire Maximizes Success

Moving From Stick Electrodes To Self-Shielded Flux-Cored Welding Wire: Part One

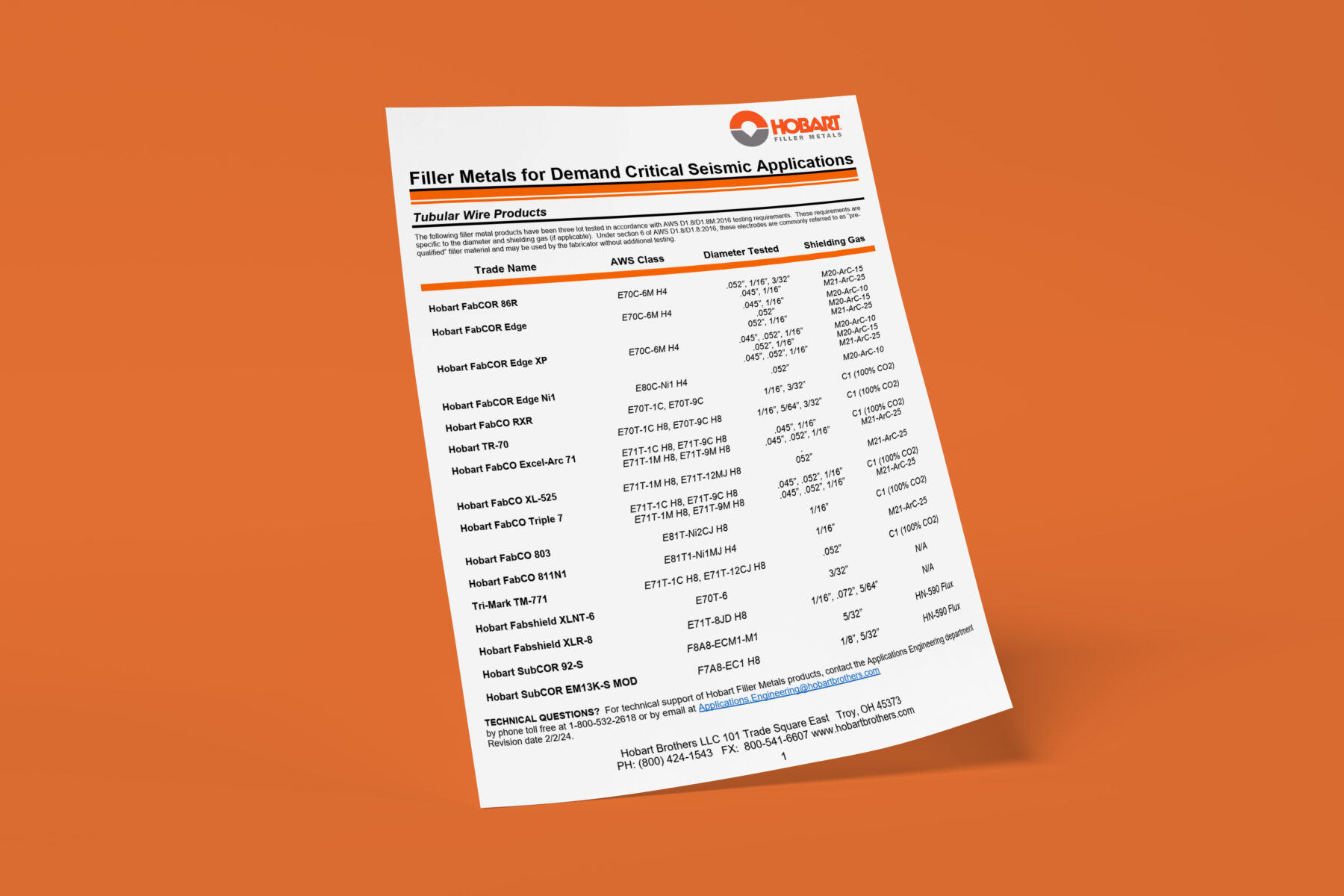

Filler Metals for Demand Critical Seismic Applications

Frequently Asked Questions

There are several regulations in the Made in America space (Buy America, Buy American, BABA, AIS). In many cases, our products meet one or more of these regulations. To confirm a product’s Buy America status, email: Applications.Engineering@hobartbrothers.com

Yes, please visit our education page for additional information: Welding Training and Education for You and Your Team

The polarity required to operate a filler metal is due to the unique electrode design, classification, and formulation

Yes, select a product on www.hobartbrothers.com and look for AWS D1.8 in the Approvals section

We offer a wide range of packages and diameters ranging from bulk packaging, like our 50-lb cans for stick electrode, or up to 1000-lb drums for tubular wire. We also have smaller 5-lb plastic packs or 10-lb hermetically sealed cans for stick electrode, and 10 to 15-lb spools for wire for a more portable solution when welding in the field. To review product-specific package offerings, select a product on our website: www.hobartbrothers.com

Hobart Borhters offers self-shielded flux cored wires sucah as Fabshield XLLR-8, stick electrode including Hobart 418, gas shielded flux cored wires like Fabco Triple 7, submerged arc wires and fluxes such as SDX EM12K paired with HA-495, and metal-cored wires like FabCOR Elevate to meet your confab project needs.

Yes, contact oe@hobartbrothers.com to include actual mechanical and chemistry data.