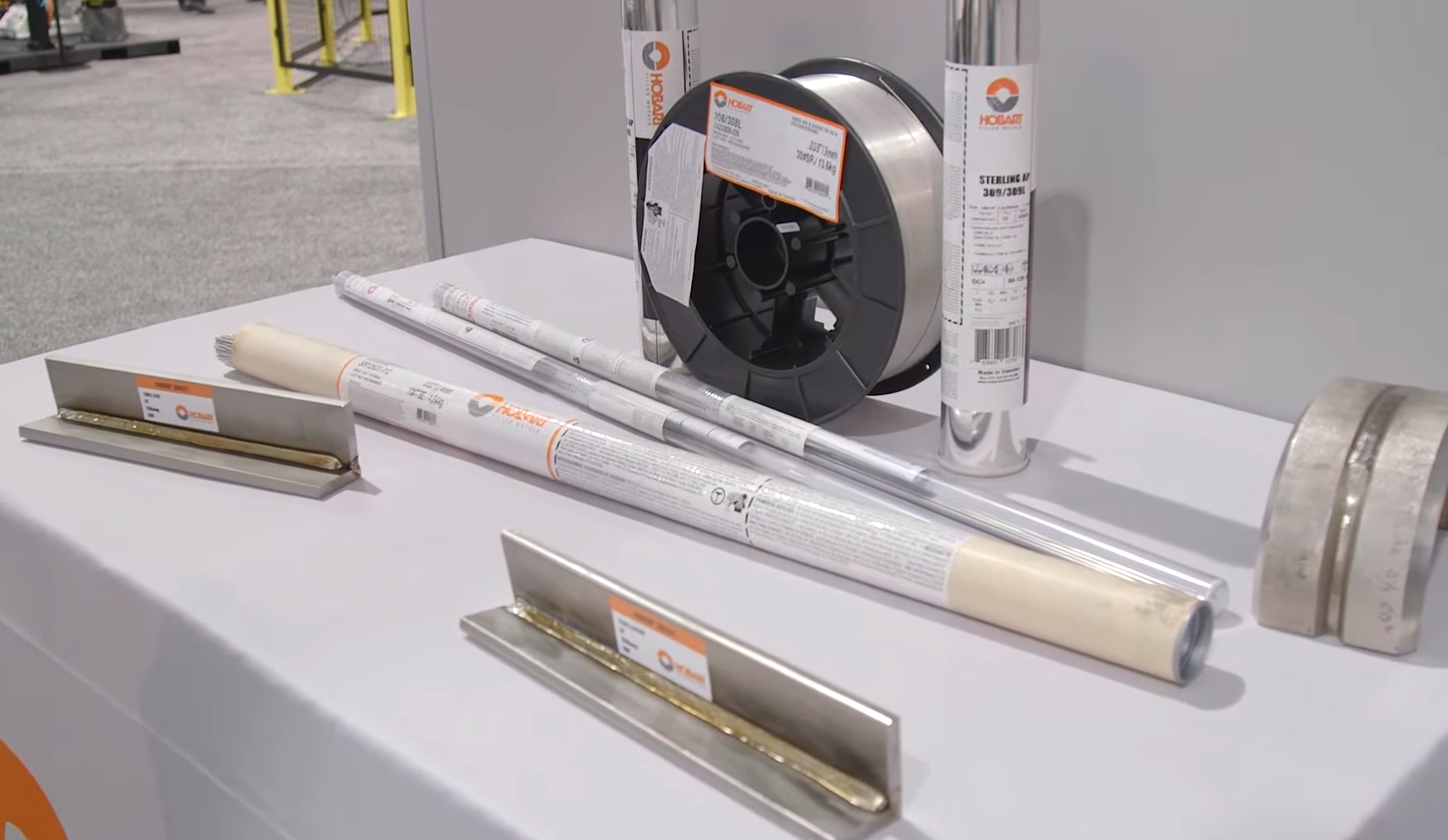

New Stainless Steel Wires Offer Easy Slag Removal

The new FabCO® 308LT1 flux-cored wire offer easy stainless steel slag removal, along with a smooth bead appearance.

This wire is specifically designed for welding austenitic stainless steel in a variety of applications. This gas-shielded flux-cored wire is used with either 100% CO2 or a 75% Ar/25% CO2 gas mixture.

Features and benefits of this stainless steel wire include:

- All position wire

- Self-detaching slag

- Spray-like arc transfer results in consistent, high-quality welds.

- High moisture resistance

- Excellent welder appeal

- Low spatter and less clean-up

- Good weld soundness and extended shelf-life

- Welds extremely well in vertical (up) position, as well as flat, horizontal and overhead.

It is important to store this stainless steel wire properly to ensure that it remains free from moisture and other contaminants. Keep the wire in a cool and dry place to avoid any exposure to moisture and other contaminants.

Watch as Hobart welding engineer Caleb Haven demonstrates. Its low spatter, smooth arc, and high deposition rates make it an attractive option for many welders and make stainless steel slag removal easy.

For more guidance on welding various metals and what filler metals to use in your industry, explore our collection of Technical Articles.